USB Type-C charging connectors: design, optimization, and interoperability

By Monolithic Power Systems

EU mandate for a common charger

In June 2022, the EU parliament approved a mandate that will require the next generation of portable devices to be compatible with USB Type-C® charging connectors. Manufacturers have until late 2024 to make their products compatible with USB Type-C cables by adding a USB Type-C connector.

Affected product types include mobile phones, digital cameras, handheld video game consoles, portable speakers, keyboards, portable navigation devices, earbuds, mice, e-readers, headsets, and headphones. Laptops are also included, though manufacturers do not need to adhere to this mandate until 2026. In 2027, the EU parliament plans to add additional devices to this mandate. It will reconvene every five years thereafter to consider other applications.

As this mandate begins to take effect, manufacturers will be required to offer a version of their product without a charging adapter; they can optionally offer an additional version with a charger included. If a consumer already owns a USB Type-C charging cable and charger, they can save money and reduce e-waste by opting for the version of the product without a new charger. It is estimated that this mandate can prevent up to 22 million pounds of e-waste each year.

This article will discuss USB Type-C connectors: how they work, how they are specified, and their typical applications, while using Monolithic Power Systems products to highlight how USB Type-C connectors can be optimized.

USB Type-C connectors

The USB Type-C, also called USB-C, specification was published in 2014, and these connectors quickly gained popularity due to their advantages over older USB connectors, such as USB Type-A. USB Type-C connectors are reversible, meaning they do not require a particular orientation when going into a port, and they are also smaller than legacy connectors, as shown in Figure 1. In particular, USB Type-C connectors can handle much higher power, which means they can be used in a wider range of portable applications.

Fig. 1: A USB Type-A connector (left) and USB Type-C (right)

Fig. 1: A USB Type-A connector (left) and USB Type-C (right)

USB Type-C power detection

USB Type-C connectors have a specific power detection and negotiation interface. Consider when a user plugs a USB Type-C cable into a product. A USB Type-A power supply constantly outputs 5 V; in contrast, the USB Type-C power supply is normally off. This is because USB Type-C connectors have a detection function in a separate configuration channel, CC, pin to determine when to turn on after detecting connections on both ends of the cable.

In addition, the CC pin allows for current-level detection and role orientation between the power supply (source) and power consumer (sink). This allows USB Type-C products to maintain compatibility with legacy 5 V USB products, while also enabling higher power detection through the use of the USB Power Delivery (USB PD) protocol, which also uses power negotiation on the CC pin.

Figure 2 shows the basics of USB Type-C power detection.

Fig. 2: USB Type-C configuration channel on the CC pin

Fig. 2: USB Type-C configuration channel on the CC pin

USB Type-C power levels

USB Type-C connectors are very powerful, and they support various newer standards, such as USB PD, USB 3.1, and DisplayPort. Older USB connectors can provide more than 7.5 W in a single direction, but USB Type-C can support single-direction and bidirectional applications up to 15 W with standard cables and minimal additional circuitry, as well as applications exceeding 15 W with USB PD compatibility.

USB PD in the standard power range (SPR) can support up to 20 V at 100 W. A recent update to the USB PD specification called extended power range (EPR) can now supply up to 240 W. In addition, USB PD allows for bidirectional power flow, meaning a device can provide or receive power, unlike single-direction connectors, such as a micro-B USB, which can only receive power. This wide power delivery range means that USB Type-C with PD can easily charge both smartphones and laptops. However, not all USB Type-C implementations support USB PD and this will be discussed in greater detail later in the article.

Table 1 shows the different power levels for different modes of operation that are compatible with USB Type-C connections.

| Mode of Operation with USB Type-C | Nominal Voltage | Max Current | Max Power Output |

| Default USB Power (USB 2.0) | 5 V | 500 mA | 2.5 W |

| Default USB Power (USB 3.2) | 5 V | 900 mA or 1.5 A (single- or dual-lane) | 4.5 W or 7.5 W |

| Default USB Power (BC1.2) | 5 V | 1.5 A | 7.5 W |

| USB Type-C 1.5A | 5 V | 1.5 A | 7.5 W |

| USB Type-C 3.0A | 5 V | 3 A | 15 W |

| USB PD SPR | Configurable up to 20 V | 3 A (5 A with e-marked cable) | 100 W |

| USB PD EPR | Configurable up to 48 V | 5 A | 240 W |

Table 1: Power outputs over a USB Type-C connector

USB Power Delivery

USB PD can provide up to 240 W of power and is capable of bidirectional operation, meaning it can supply or receive power. Non-PD USB Type-C sources can supply up to 15 W of power at 5 V/3 A, while USB PD sources can go above 5 V, and thus exceed 15 W. Increased power delivery means that USB PD can charge devices much faster than legacy connectors. In addition, USB PD specifies the voltage and current tolerances for both the source and sink.

For products that support USB PD, there are two additional chips required (called PD controllers): one chip in the power supply (source), and a second chip in the portable device (sink). Using these two chips, the product communicates through the cable using the CC lines of each chip. The source communicates the voltage and current that it can support, while the sink, such as a speaker or phone, communicates the voltage and current that it requires. The source adjusts its output accordingly to ensure that the optimal voltage and current are supplied to the sink. Because these two chips increase costs, USB PD is typically not implemented for applications that can get by with less than 15 W of power.

Figure 3 shows USB PD communication.

Fig. 3: Communication over a USB PD interface

Fig. 3: Communication over a USB PD interface

The requirement to implement USB PD for applications needing more than 15 W is part of the EU mandate. Although some companies have unique protocols to negotiate for higher voltage and power, the new EU mandate states that these other methods are not allowed, in order to ensure interoperability between different charging adapters and devices, and to maintain safe operation. Furthermore, using a protocol other than USB PD to increase the voltage above 5 V is specifically banned in the USB Type-C specification due to safety and interoperability concerns.

For example, there are certain smartphones that utilize the USB Type-C connector. However, these phones only charge fast when plugged into a specific charging adapter with a specific cable because the product does not use USB PD. That means an off-the-shelf USB PD charging adapter may not charge the product quickly, even if its power rating is equivalent to the in-box adapter. This causes user confusion, adds to e-waste, and makes the product’s safety and reliability dependent on a specific manufacturer’s confidential charging protocol.

USB Type-C connectors: compliance, safety, and optimization

As manufacturers work to implement USB Type-C technology in their products, it is vital for them to recognize the difference between an implementation that is physically sufficient versus one that meets the requirements of the USB Type-C specification. A manufacturer can decide whether to submit their product for USB Type-C certification, which means the USB Type-C logo can be used on the product.

Rather than obtain the certification, some manufacturers try to reduce costs by meeting the minimum physical requirement for a USB Type-C connector that can supply or receive power. Although this approach reduces cost, the missing features and functionality can result in safety risks that could lead to damage to the device itself or other products connected to it.

Uncertified USB Type-C products can experience a myriad of failures and pose safety concerns, but there are ways to mitigate these issues with robust protection functions that protect the cable, source, and sink. Some of these concerns — as well their solutions — are discussed below. Point 1 describes a benefit of certified USB Type-C sinks, while the remaining points describe additional protection and optimization features offered by Monolithic Power Systems’ power management ICs.

- Input-current detection on the CC pin: consider USB Type-C implementations without PD compatibility, for those below 15 W. A USB Type-C source can advertise three current levels: default, 1.5 A, and 3 A, where default is meant to be backwards-compatible with older USB sources, from 100 mA to 1.5 A.

It is important for the sink to detect the source’s CC pin advertisement to determine how much current can be drawn. A USB Type-C compliant sink can detect the value on the CC pin and adjust its input current limit accordingly to avoid drawing too much current from the source. Once a current limit is set, the sink can dynamically change how much current it draws as the source changes its advertisement.

To reduce costs, some manufacturers place two resistors on the sink’s CC pins so that the source turns on 5 V when the cable is connected between them, as shown in Figure 4. This configuration is only allowed if the sink does not draw more than the default current, as negotiated over the USB data lines.

Fig. 4: Input current detection using resistors

Fig. 4: Input current detection using resistors

When resistors are used instead of proper input current detection, the sink does not look at its own CC pin. For example, if a computer has a USB Type-A port, it may only be capable of supplying 500 mA. If a sink does not recognize that its source can only supply 500 mA, it might try to draw 3 A, which would create an over-current condition and potentially damage the source’s port.

Charger ICs in the sink typically also have an input-voltage loop, but this only prevents the input voltage from dropping too low. There is no guarantee that the sink charger IC’s minimum input-voltage loop will react quickly enough, or be set high enough, to prevent damage to the source. Therefore, this protection should be treated as a backup to CC current detection and input current limiting, instead of the primary protection circuit.

Note that the simple resistor pull-down implementation can be used for sink applications that do not consume more than 1.5 A and implement BC 1.2 detection, as shown below.

- BC1.2 and proprietary charger detection: BC1.2 is the standard that defines how a sink can detect the current output capability of a source that either does not have a USB Type-C connector, a legacy source, or supplies less than 1.5 A. This detection process is executed by using the D+ and D- pins. Proprietary charger detection adds to BC1.2 by allowing the sink to detect common charging adapters.

The USB Type-C specification does not require sinks to implement BC1.2 if they support CC pin detection. However, if the sink does not implement BC1.2, then only a maximum of 500 mA can safely be drawn from a USB 2.0 source advertising a default current on the CC pin. Adding BC1.2 to the sink allows for up to 1.5 A to be drawn from sources advertising a default current, such as legacy sources: this supplies more power, shortens charging time, and leads to a better end user experience.

- Non-compliant legacy cable detection: a legacy cable is defined as having a USB Type-C connector on one end and a different, legacy USB connector on the other end. To advertise the current level to the sink, legacy USB Type-A cables must implement a 56 kΩ pull-up resistor from the CC pin to the VBUS pin on the USB Type-C side. However, there are non-compliant legacy USB Type-C cables that are either missing a pull-up resistor, floating or shorted, or they have a resistor of the incorrect value.

This can lead to incorrect input current limit detection, as described with input current detection using the CC pin, or to an over-voltage event on the sink’s CC pin, since the sink’s CC pin may be directly shorted to VBUS. To avoid these problems, the USB Type-C sink device should be able to detect when a non-compliant legacy USB Type-C cable is attached, to protect the CC pins.

- Over-voltage protection for the VBUS and CC pins: SPR PD charging adapters can go up to 21 V, and non-PD charging adapters can go up to 5.5 V. Therefore, it is recommended to protect VBUS up to at least 21 V in case there is a PD adapter malfunction or a VBUS transient surge occurs.

Under normal operating conditions, the CC pin should never experience a high voltage, since CC is either not physically connected to VBUS, for instance with a USB Type-C cable, or it is connected to VBUS through a 56 kΩ resistor, with a legacy cable. However, since the CC pins are physically located adjacent to the VBUS pins, it is possible for debris in the connector to create a short between them. It is also possible that a non-compliant cable could short VBUS to the CC pin. To protect the CC pins against both use cases, over-voltage protection is highly recommended.

- Connector moisture detection: Moisture on the connector can cause corrosion and damage over time, which can lead to shorted or open pins. This is especially common in dual-role port or source applications, where the product applies a pull-up voltage or current to the CC pin while advertising source mode. If the product makes contact with any electrolytic liquid, such as water, then the device should be able detect this, force the product into sink mode by removing the CC pull-up bias and VBus, and alert the user.

- Connector temperature monitoring: the USB Type-C connector has four VBUS pins and four ground pins in parallel. As the connector gathers debris or wears out over time, some pins may experience open-circuit conditions, which disrupts current flow and results in current crowding in the remaining pins. This additional current heats the connector. To avoid overheating and possible permanent damage, a USB Type-C product should be able to monitor these conditions, alert the user if the connector must be cleaned, and reduce its current to lower the temperature.

Use case for safety and optimization

Consider a cable that does not have USB Type-C on both ends. A charger IC could detect when a device has been plugged in, analyze the current limit, and determine whether the cables are compliant. For USB Type-C to USB Type-C cables, the CC pin passes all the way through the cable, the source supply applies pull-ups, and then the sink, with charger IC, applies pull-downs.

For legacy Type-A to Type-C cables, however, a resistor pulls up the CC voltage to VBUS. A few years ago, many of these cables were non-compliant. This led the CC controller or chip to detect a higher current than the cable actually supported, meaning that a source with a 500 mA current capability would appear to advertise a 3 A current capability through the cable. In this scenario, devices such as the MP2722 switch-mode battery charger for lithium-ion and lithium-polymer batteries, described in more detail below, can detect whether the cable is non-compliant and properly set the input current limit, as shown in Figure 5.

Fig. 5: Features of the Monolithic Power Systems MP2722 switch-mode battery charger

Fig. 5: Features of the Monolithic Power Systems MP2722 switch-mode battery charger

A safe and compliant solution has a charger, over-voltage protection chip, and CC controller chip, or a chip that detects the CC pin. Some manufacturers forgo the CC pin detection and the over-voltage protection chip in the sink to reduce costs. While this implementation electrically functions for a sink, it does not ensure the safety of the attached products. Furthermore, this cannot be used for dual-role power applications.

Monolithic Power Systems products for USB Type-C connections

Monolithic Power Systems offers solutions that cover a wide range of USB applications. Rather than settle for parts that only meet the bare minimum implementation for USB Type-C connections, these products provide additional benefits for compliance, safety, and functionality.

A USB Type-C capable power management IC should be selected for the specific application. Generally, these products can be separated into two distinct categories: applications that require ≤15 W, and applications that exceed 15 W.

For applications ≤15 W, end product types include smartphones, point-of-sale (POS) systems, speakers, e-cigarettes, headphones, smartwatches, and some tablets. These products do not necessarily require USB PD compatibility, and can simply rely on a CC controller to determine current level and device power role. Not requiring USB PD reduces cost because neither the source nor the sink require an additional PD controller IC. Most products requiring less than 15 W use a single-cell battery or multiple cells in parallel. These products can be sink, source, or dual-role power solutions:

- Sink only: For applications that only require a sink, a single-direction, 5 V, 15 W charger IC can be used to charge the battery and perform sink CC controller operation. The MP2722 is an excellent choice for these applications.

- Source only: Source-only applications include power supplies and car chargers. These applications do not need a battery, so all that is required is a 5 V regulator and a source CC controller.

- Dual-role power (DRP): DRP solutions are bidirectional, meaning they can both sink and source power. The MP2722 is a bidirectional, 5 V, 15 W charger IC that can both charge the battery, as well as provide a 5 V output and DRP CC controller.

For applications that require >15 W — laptops, power banks, large speakers, power tools, medical devices, and high-end smartphones and tablets — USB PD compatibility is required.

These solutions provide DRP, and are typically organized into two main categories:

- Single-cell USB PD: single-cell USB PD solutions, or multiple cells in parallel, are typically used in mid- to high-end phones, tablets, and power banks with a power rating of more than 20 W. The MP2731 buck charger is designed for implementation in these applications. For more details, see the MP2731 USB PD reference design.

- 2- to 4-series cell USB PD: USB PD solutions with multiple cells in series are typically used for laptops, tablets, gaming devices, medical equipment and power banks that require more than 20 W. These applications require a buck-boost charger, such as the MP2760 or MP2651, which can both be used to create a complete USB PD solution.

MP2722 USB Type-C battery charger

The MP2722 is a highly integrated, 5 V, switch-mode battery charger for lithium-ion and lithium-polymer batteries. This battery charger provides narrow-voltage dc (NVDC) power path management, and can supply up to a 5 A charge current. It is fully compliant with USB Type-C 1.3 and provides an integrated CC DRP controller for bidirectional 15 W regulation in source or sink modes. The MP2722 also integrates 26 V over-voltage protection on the VBUS pin and 22 V over-voltage protection on the CC pins, and an I2C interface for flexible configurations.

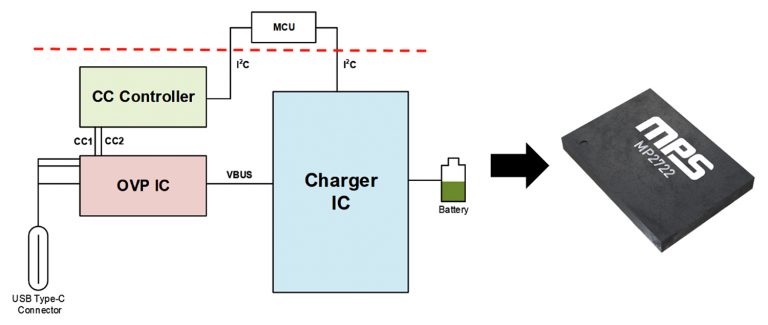

Other 15 W DRP USB Type-C implementations require a separate charger IC, DRP CC controller, and an over-voltage protection IC for the VBUS and CC pins. The MP2722 integrates all three of these functions into a single chip for maximum area and cost savings, as shown in Figure 6.

Fig. 6: Comparison of a traditional solution for USB Type-C charging with the MP2722

Fig. 6: Comparison of a traditional solution for USB Type-C charging with the MP2722

In addition, the MP2722 supports advanced USB Type-C features, which make it compliant, safe, and highly optimized. These features include connector temperature monitoring, connector moisture detection, non-compliant legacy cable detection, and BC1.2 for optimization with legacy charging adapters. Due to its small solution size and complete USB Type-C feature integration, the MP2722 is ideal for any 1-series cell application for USB Type-C connectivity.

MP2731 USB PD battery charger

The MP2731 is a 15 V, 4.5 A, switch-mode battery charger with NVDC power path, as well as an integrated ADC and I2C interface. A reference design using the MP2731 and external USB PD controller provides a complete solution for USB PD applications while complying with USB PD 3.0 specifications.

This design offers a DRP USB Type-C port that allows bidirectional power and fast charging in sink mode. When a USB input is present, the charger is configured as a sink and charges the battery. If a USB PD sink is connected to the port, the charger acts as a source and supplies a regulated output voltage using the battery as the power source.

The MP2731 PD design can provide up to 18 W of PD fast charging. In addition, the MP2731 integrates an input-blocking FET, which makes using an additional USB PD input FET configuration optional, reducing BOM cost and PCB size. This design is recommended for any 1-series cell applications requiring faster charging through the implementation of USB PD.

MP2760 and MP2651 boost, buck and buck-boost battery charger

The MP2760 is a 20 V, 6 A, buck-boost charger with NVDC power path for battery packs with from 1 to 4 cells in series. The charger features four integrated switching FETs, ADC, and I2C interface in an extremely compact solution. It can operate in boost mode, buck mode, and buck-boost mode, depending on the input and battery voltages. By operating in reverse, the MP2760 can power the input from the battery in source mode.

The MP2760 battery charger is compliant with USB PD DRP operation across the full range of SPR voltage and current levels.

The MP2651 is pin-compatible with the MP2760, but is optimized for applications that do not require an NVDC power path, such as power banks, power tools, and battery back-up products.

Both devices are implemented with the CCG3PA USB PD controller to create a complete USB PD solution, shown in Figure 7. This solution contains a DRP USB Type-C port for bidirectional operation. If an adapter is inserted, the port can act as a sink and charge the battery. If a sink is inserted, the port can act as a source to power the USB using the battery. For additional flexibility, both parts can be configured via an I2C interface. This design is ideal for applications such as speakers, tablets, medical devices, point-of-sale systems, drones, and cameras.

Fig. 7: USB PD solution based on the MP2760

Fig. 7: USB PD solution based on the MP2760

Conclusion

USB Type-C connectors are versatile, incredibly small compared to older connectors, backwards-compatible with older USB standards, and can deliver high power up to 240 W.

By following the specifications for USB Type-C and USB PD and optimizations discussed in this article, manufacturers help to maintain interoperability between products, provide protections that can extend the product’s lifetime, and contribute to the EU’s goal of e-waste reduction.

Although the common charger mandate in the EU is a recent development, MPS has long been creating charger ICs and battery management devices designed to cover a wide range of USB Type-C and USB PD applications. Buyers and manufacturers of portable applications can benefit from its extensive portfolio as USB Type-C connectors become more and more common worldwide.