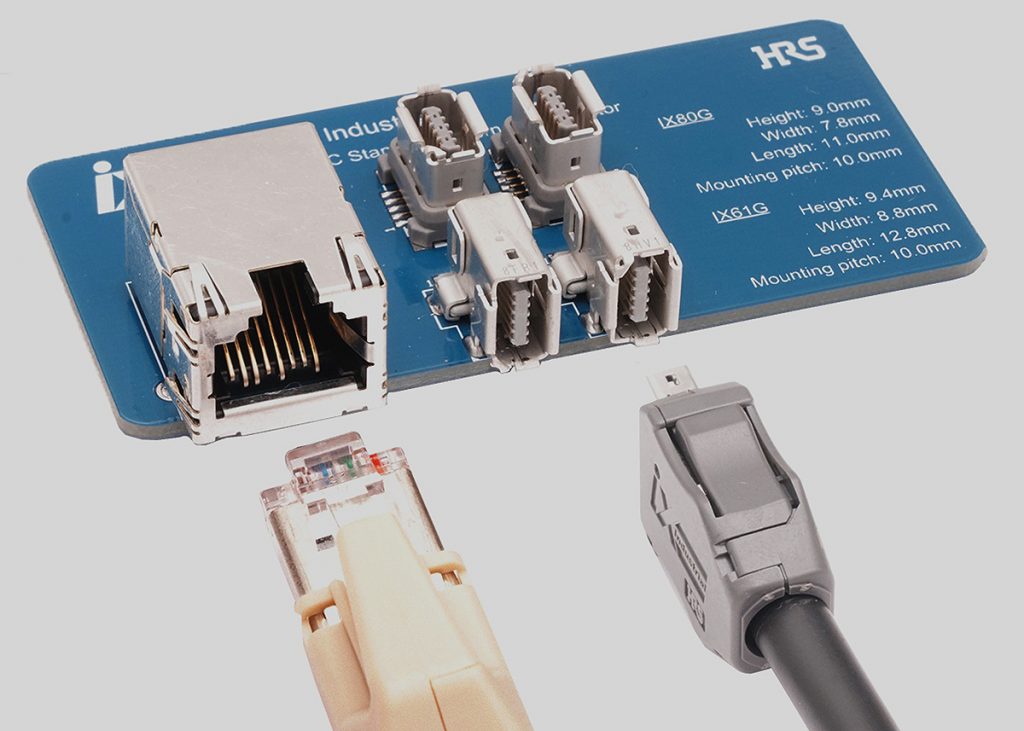

Compact industrial Ethernet connectors provide board space savings of up to 75%

ix Industrial™ connectors support data rates up to 10 Gbits/s. Available in a wide range of mounting styles for various cable sizes, the ix Industrial connectors can be positioned closely side-by-side on a single PCB.

Hirose supplies a rugged Ethernet connector which combines a small, robust design with high-speed data-transmission capabilities. Intended for use in industrial automation and manufacturing environments, the ix Industrial™ connectors combine high-speed performance and a compact design with high reliability and design flexibility.

The connector occupies up to 75% less board space than RJ45 connector systems, and up to 28% less than competing snap-in I/O connectors. Supporting CAT5e and CAT6A cabling, the ix Industrial series connector integrates shielding against EMI and electro-static discharge to provide for safe and secure transmission at data rates up to 10 Gbits/s.

The ix Industrial series is available with two keying codes, one for Ethernet and the other for non-Ethernet applications. The connectors are compliant with the IEC 61076-3-124 standard. The ix Industrial plug is supplied with both solder and insulation displacement contact (IDC) terminations, giving the flexibility to use it with a range of cable sizes.Offered in upright right-angle, horizontal right-angle, vertical, and panel-mount inline versions, the ix Industrial connectors enable designers to save board space, for instance, the dimensions of the upright right-angle receptacle are just 8.8 mm x 9.4 mm x 12.8 mm. The connectors can be mounted in parallel with a pitch distance of only 10 mm. The narrow width of the receptacle is particularly beneficial when multiple connectors are positioned on a single PCB side-by-side.

Featuring a rugged and reliable design, the snap-in I/O connector has a positive metal lock with a pre-load spring mechanism which provides a clear tactile click and ensures complete, secure mating. The pre-loaded springs prevent unintended cable removal, and extend the operating life to more than 5,000 mating/unmating cycles.

The receptacle shell is mounted on the PCB via through-hole solder legs to enhance PCB retention and to resist the wrenching of the cable assembly. The wire-termination unit and cable clamp are integrated into a single plug shell, which prevents the connecting part of the cable assembly from being affected by the load on the cable.