Power and motor-control solutions for autonomous mobile robots

Designs benefit from careful evaluation of components’ efficiency, precision and ease of integration. This review of the portfolio of onsemi products suggests ideal components for use in AMRs.

Autonomous mobile robots (AMRs) offer many benefits including improved safety and higher efficiency compared to vehicles piloted by humans. The safe and independent operation of these complex systems requires the careful integration of many technologies. The design considerations for two vital AMR systems, power management, and motion control, can be implemented with the latest components from onsemi.

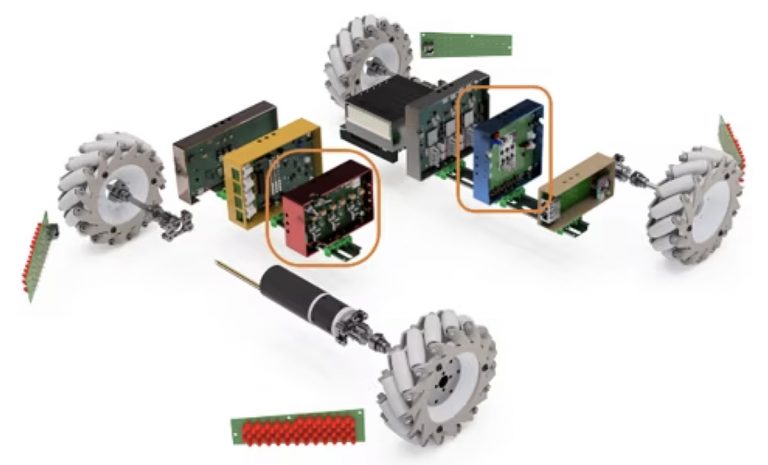

Fig. 1: The onsemi demonstration design for an autonomous mobile robot

Powering AMRs

The design of the power system and the selection of its power components are heavily influenced by the use case’s requirement for battery run-time between charges. Important performance characteristics and parameters to consider when designing the power supply for an AMR are shown in Figure 1 and include:

- Energy density

- Voltage and current requirements

- Efficiency

- Size and weight

AMRs commonly use lithium-ion batteries because they offer high energy density and long life. Power management units regulate power flow from the battery to other components. Voltage and current levels are controlled by switching converters and voltage regulators.

Alongside power-conversion circuits, battery management systems (BMS) in an AMR monitor the state of charge, temperature, and current of a battery to ensure the AMR operates safely and efficiently. The onboard battery charger’s specifications depend on the battery type, capacity, and voltage.

For the motor-control system, intelligent power modules (IPMs) provide high-power switching for the motor-control system. Inside the IPM, gate drivers provide the appropriate signal to turn on and off the internal power switches.

Power factor correction (PFC) controllers enhance a power system’s overall efficiency. Power components from onsemi are ideal for ac-dc power supply topologies such as a totem-pole PFC front end, or an LLC resonant dc-dc converter. They are also ideal for high-voltage dc-dc converter power stages, providing the basis for the efficient and high-density fast battery charger in an AMR, shown in Figure 2.

Fig. 2: Power systems in an AMR

Fig. 2: Power systems in an AMR

Motor design for AMR actuatorsThe choice of motor-driven actuators is important in AMRs since they enable the arms and wheels of the machine to move, as shown in Figure 3. AMRs require high-torque, fast actuators that offer high efficiency while also minimizing size and weight. In designing an actuator, engineers will evaluate components such as brushless dc (BLDC) motors, motor controllers, MOSFETs, universal controller boards, and gate drivers.

BLDC motors offer several advantages over brushed motors. They are used in AMRs due to their high efficiency, low noise, and low maintenance requirements. Their control, however, requires complex algorithms and a suitable driver. Three-phase BLDC motors are widely used in robotics and industrial drives.

Fig. 3: Motor-control systems in an AMR

Three-phase BLDC motor controllers can be a fully integrated combination of a motor power stage and a controller, backed by an embedded control algorithm. Alternatively, a dedicated microcontroller running a motor-control algorithm can be used alongside a discrete power circuit.

Three-phase motors are driven by power switches that respond to a PWM control signal. These switches can be made from silicon or from a wide bandgap material, either silicon carbide (SiC) or gallium nitride (GaN).

The onsemi portfolio of BLDC motor-control solutions includes the ECS640A ecoSpin™ motor controller, the NCP81075 gate driver, and a power board, which can be used to accelerate AMR actuator development.

Also from onsemi is a universal controller board for motor control, a system-on-module (SoM) based on the XilinxM® Zynq®-7000 system-on-chip, which supports precision motion control, and can also be used for advanced artificial intelligence (AI) functions.

onsemi also offers shielded-gate trench MOSFETs that have voltage ratings ranging from 30 V to 150 V, in various package options, and new T10 technology-based 30 V to 40 V and 80 V MOSFETs for low- and medium-voltage applications. T10 devices are divided into two categories for power conversion and motor control.

The T10M devices for motor control offer best-in-class on-resistance, a 10% improvement in unclamped inductive switching capability, and excellent body-diode softness, which lessens susceptibility to voltage spikes and EMI problems.

For three-phase BLDC motors in high-power applications, onsemi recommends PTNG technology-based MOSFETs rated at 80 V, 100 V, 120 V, or 150 V.

The NTMTSC1D6N10MC, NTMTSC4D3N15MC, NTBLS1D5N10MC, and NTBLS4D3N15MC MOSFETs meet the requirements of high-performance applications.