Simplicity and efficiency: 1,700 V integrated flyback controllers based on SiC MOSFET technology set a new trend

By Akif Hakki Polat

Eastern Europe Analog and Power Specialist Field Application Engineer, Future Electronics

Read this to find out about:

- The drawbacks of a discrete approach to high-voltage flyback converter design

- The case for using an integrated SiC flyback controller with internal 1,700 V MOSFET

- A comparison of 1,700 V-rated integrated flyback controllers from Power Integrations and ROHM Semiconductor

The flyback converter can lay a claim to be the most widely used topology for ac-dc conversion in systems supplying a load of up to around 100 W. It is particularly suitable for applications that require isolation, or in which the input-to-output voltage ratio is high.

The flyback converter is most often used in mains-powered systems, which are covered by a universal input-voltage range of around 85 V to 265 V ac. But it is also suitable for industrial applications in which the input-voltage range can extend from 40 V to 440 V ac. The flyback converter can also be used for dc-dc conversion over a wide input-output voltage spread: in some industrial and automotive applications, the dc input voltage might be as high as 1,000 V dc. And of course the input voltage in the application affects the specification of the breakdown voltage of the power switches used in the converter.

In the past, this has limited the ability of power-system developers to take full advantage of an integrated flyback converter controller, which is simpler to design into a board layout, occupies less space and requires fewer components than a comparable discrete circuit. At lower voltages, the integrated flyback controller has often been the preferred option, but for a long time the highest breakdown-voltage ratings for the silicon MOSFET embedded in integrated controllers were in the range 800 V to 1,000 V, insufficient on its own for many very high-voltage applications.

Now the maturing of the market for MOSFETs based on the wide bandgap silicon carbide (SiC) material has made it possible to dramatically extend the voltage capability of integrated flyback controllers up to 1,700 V.

This article helps the reader to evaluate products from the two pioneering manufacturers that have led the way in the market for SiC MOSFET-enabled integrated flyback controllers.

The drawbacks of a discrete approach to high-voltage flyback converter design

In an integrated flyback controller, the control circuitry, gate driver and power switch are all housed in a single package. This streamlines the selection of components as well as simplifying the board design. The reduced board footprint compared to a discrete system is particularly helpful in designs that are subject to space constraints.

But in systems that require the power switch to provide a voltage rating above 1,000 V, designers have been forced to work around the limited breakdown-voltage capability of integrated flyback controllers.

One option is to relinquish the benefits of integration, and to use a stand-alone flyback controller with a discrete high-voltage silicon MOSFET. The other approach is to continue to use an integrated flyback controller with a voltage rating limited to the range 800 V to 1,000 V, but to reinforce its internal MOSFET with a cascode-connected external MOSFET.

The problem with the first approach is the maximum breakdown voltage of a conventional silicon MOSFET: the application for the design is limited to systems that are guaranteed to operate at lower than 1,200 V.

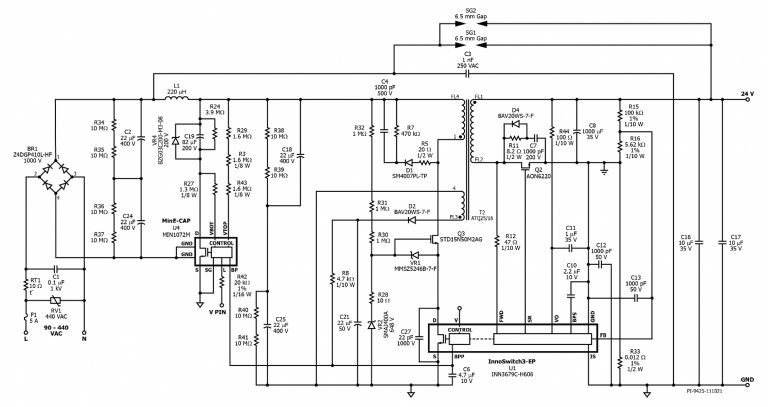

The second approach is not hamstrung in the same way, because the withstand voltages of the integrated and the external switch are additive. But this comes at the cost of a more complex power-system design. Figure 1 shows the schematic of a typical circuit in a cascode MOSFET configuration, based on a 60 W isolated StackFET™ flyback power supply which uses a Power Integrations InnoSwitch™ 3-EP flyback converter, part number INN3679C-H606, with a MinE-CAP™ MIN1072M bulk capacitor miniaturization and inrush management IC.

When using the cascode configuration, proper functioning of the converter requires the designer to take great care over the board layout and component selection. What is more, the use of conventional silicon MOSFETs in such very high-voltage applications entails higher switching losses than in a circuit using a single SiC MOSFET. This is in part because of the inherent high efficiency of a SiC MOSFET. But in addition, in the cascode configuration losses are higher because the two MOSFETs in series both conduct during on-time.

Fig. 1: Schematic of a flyback converter circuit which includes an external cascode-connected MOSFET. (Image credit: Power Integrations, from Design Example Report 712.)

Integrated options for very high-voltage flyback converters

So the two options for developing flyback converters with a power-switch voltage rating above 1,200 V both have their drawbacks. The availability of SiC MOSFET-based integrated flyback controllers that have a breakdown voltage rating of 1,700 V now means that these drawbacks can be avoided.

Devices from Power Integrations and ROHM Semiconductor provide an integrated solution for applications that operate from a very high-voltage ac or dc input without the need to use external power switches. They also let power-system designers benefit from the much lower on-resistance of SiC MOSFETs by comparison with the silicon equivalent, resulting in higher conversion efficiency, less waste heat and higher power density.

The Power Integrations SiC MOSFET flyback controllers are available in two series:

- InnoSwitch3-EP series – the INN3647C, which has a maximum output power of 50 W, and the 70 W INN3649C

- InnoSwitch3-AQ series of automotive-qualified controllers is comprised of the 50 W-rated INN3947CQ and the 70 W INN3949CQ

ROHM also supplies its SiC flyback controller, an industrial-grade device, in two versions, but here the difference between the two is in their packaging: the BM2SC12xFP2-LBZ is a surface-mount device with a higher creepage distance, and the BM2SCQ12xT-LBZ is in a through-hole package.

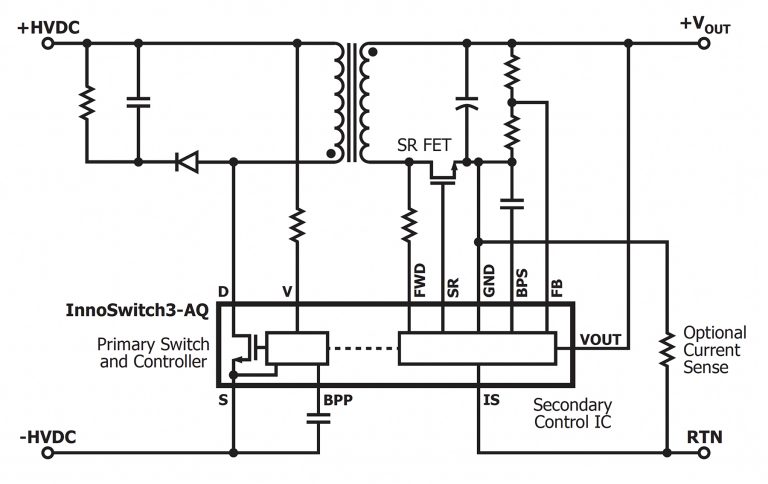

A typical application circuit for the Power Integrations controller is shown in Figure 2.

Fig. 2: Simplified typical application circuit for the Power Integrations InnoSwitch3-AQ flyback controller. (Image credit: Power Integrations, from InnoSwitch3-AQ datasheet.)

Figure 2 provides a striking illustration of the benefits of integration: this circuit contains few external components. In particular, it includes no external current-sense resistor on the primary side. Instead, two current-limit levels can be set by changing the value of the capacitor connected to the BPP pin, which selects one of two current limit levels.

On the secondary side, a standard diode can be used instead of a synchronous rectification (SR) MOSFET. The SR pin must be tied to ground to disable the synchronous rectification function. Quasi-resonant operation is controlled via the FWD pin on the secondary side.

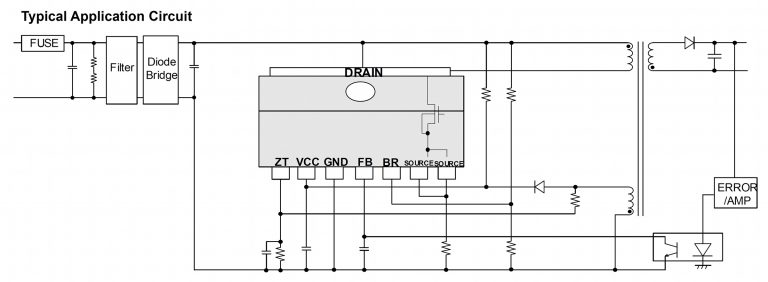

A similar simplicity can be achieved in industrial applications by using a ROHM integrated flyback controller, as shown by the application circuit in Figure 3.

Fig. 3: Simplified typical application circuit for the ROHM BM2SC12xFP2-LBZ flyback controller. (Image credit: ROHM Semiconductor, from BM2SC12xFP2-LBZ series datasheet.)

In contrast to the Power Integrations controller, the ROHM controller’s current-sensing scheme needs an external sensing resistor connected between the Source pin of the internal MOSFET and ground. This external resistor gives the designer the freedom to set different current-limit values by selecting the value of the current-sense resistor.

Quasi-resonant operation is controlled by sensing the bias winding voltage via divider resistors on the primary side.

Comparing the two integrated controllers

There are many more similarities between the Power Integrations and the ROHM parts than there are differences. The most important features are common to both:

- A high level of integration, which simplifies the circuit design, and reduces component count and system size

- High conversion efficiency and low power loss, a result of the very low switching losses in the internal SiC MOSFET. For instance, ROHM states that the BM2SC12xFP2-LBZ can be used in circuits supplying up to a 48 W load with no requirement for a heat-sink thanks to the small amount of waste heat generated by this efficient device.

The clearest difference between the two parts is in the range of applications which they support. The ROHM controllers and the Power Integrations InnoSwitch3-EP are for use in industrial applications, typical examples include the auxiliary power supply for high-voltage rectifiers, inverters, motor drivers, solar inverters, and high-voltage metering devices.

But Power Integrations also supplies an automotive-qualified series, the InnoSwitch3-AQ, which is suitable for applications such as the inverter of an electric vehicle’s traction motor or its on-board charger.

The other important difference is in the ROHM controller’s requirement for an external current-sense resistor, which the Power Integrations controllers do not need. Designers using the Power Integrations controllers can therefore benefit from a lower component count and avoid the bill-of-materials cost of the resistor. But on the other hand, the ROHM controller gives the designer the freedom to set any current limit, whereas the Power Integrations controller only provides a choice of two pre-set current limit values.

In this context, it is also worth pointing out that the Power Integrations controllers include integrated FluxLink isolated feedback signaling, whereas the ROHM parts require an external optocoupler or other isolated feedback link.

First to a growing market?

Both Power Integrations and ROHM have stolen a march on the rest of the industry, pioneering the development of devices which combine high integration with a 1,700 V rating for use in very high-voltage systems. Here at Future Electronics, we expect the benefits of integration and efficiency in these integrated flyback controllers to be popular with industrial OEMs and, in the case of the INN3947CQ and INN3949CQ, with automotive OEMs.

Of course time will tell, but other manufacturers have excellent SiC MOSFET manufacturing capabilities, and we can expect to see more new integrated flyback controllers with an embedded SiC power switch reach the market in the coming months and years.