Connectors reduce applied cost of assembling cable harnesses

The MTA 100 and MTA 156 series from TE Connectivity support mass termination assembly to reduce the labor required to connect multiple cables.

TE Connectivity (TE) provides families of wire-to-board and wire-to-wire connectors for low-power and signal applications that greatly reduce the cost of terminating cable or harness assemblies.

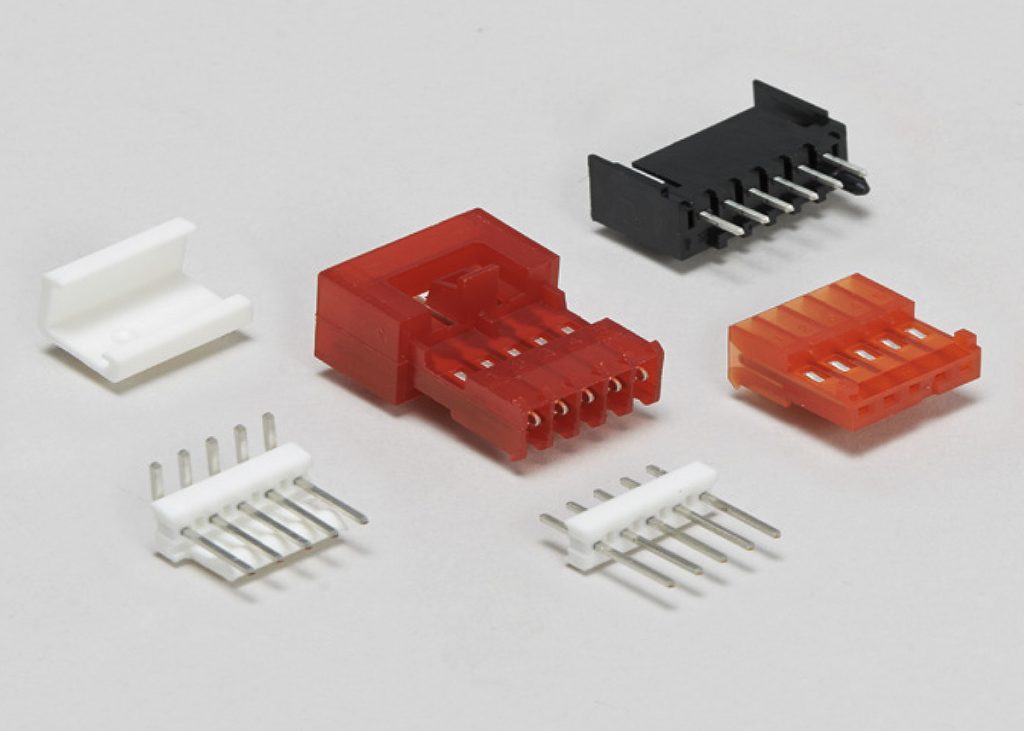

The MTA 100 and MTA 156 connectors feature insulation displacement contact (IDC) technology to support mass termination assembly processes. By enabling the mass termination of wires, they reduce the manual labor required to assemble harnesses, and so lower the applied cost.

The MTA 100 connectors offer 0.10” (2.54 mm) centerline spacing while still allowing for up to 28 positions. The maximum current rating is 5 A. The MTA 156 connectors offer 0.156” (3.96 mm) centerline spacing and from two to 24 positions. The maximum current rating is 7 A.

Housings feature styles that include both closed-end and feed-through connectors with locking ramps, both with and without polarizing tabs. For higher quality and easier handling, MTA 100 and MTA 156 connectors offer one-step assembly, and require no wire stripping. Use of these connectors eliminates the risk of contact damage, and results in fewer wiring errors, simpler tooling, and simple maintenance and repair.

The connectors offer numerous options including colored housings and various types of plated contacts.

TE, TE Connectivity and TE connectivity (logo) are trademarks owned or licensed by the TE Connectivity Ltd. family of companies.